Act As Your Own Manufacturing Team

✓ Dedicated Project Manage ✓ Dedicated Engineer ✓ Dedicated Production Work-shop

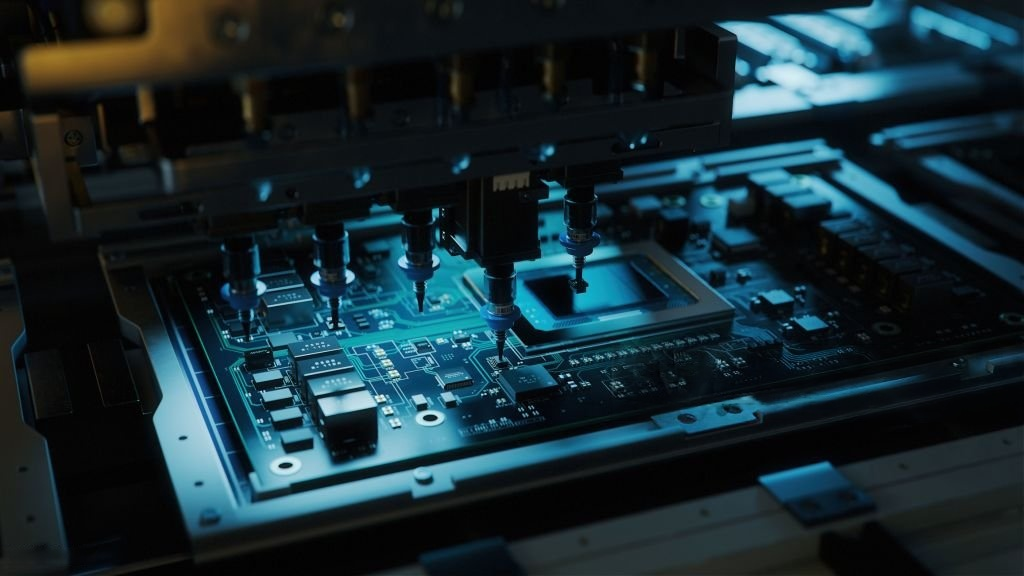

End-to-End Electronic Manufacturing Services With Turnkey Capability

Delivering quality PCB Manufacturing, Turnkey PCB Assembly, Box build Assembly with plastic injection molding, cable assemblies & wire harnesses, IoT Device Contract Manufacturing and more.

Our Values

Engineering-driven electronics manufacturing for hardware teams building complex products in low-to-mid volume. From prototype and NPI to stable production — without managing multiple suppliers.

01

Engineer-to-Engineer Collaboration

Your project is reviewed by engineers who understand design files, tolerances, and production risks, ensuring issues are resolved early—not just sales quoting.

02

Flexible Supply Chain for Real-World Production

We support low- to mid-volume builds with adaptable sourcing strategies, helping you manage BOM changes, availability issues, and cost control without disruption.

03

Accountable End-to-End EMS With Turnkey Capability

From PCB and PCBA to Product assembly and testing, one responsible team manages the entire process — eliminating handoffs, confusion, and finger-pointing.

Manufacturing Solutions

Engineering, Project Management & End-to-End Manufacturing Solutions

From early prototypes to stable production,

We manage the entire process so you don’t have to coordinate multiple vendors or resolve cross-vendor issues.

Printed Circuit Board Manufacturing

Turnkey PCB Assembly

Box Build Turneky Assembly

Custom Cable and Wire Harness

Plastic Injection Molded Parts

IoT Device Contract Manufacturing

Supporting Products Beyond the Drawing Board

From Design to Delivery — With Fewer Surprises for You

When your product leaves the drawing board, the real risks begin. What you need is not just a factory — but a partner who helps you avoid costly mistakes, delays, and rework.

With Helptron, you don’t have to chase answers or fix issues after production starts. You gain a team that works with you, thinking ahead to protect your timeline, budget, and product reliability.

Our focus is simple:

Not just to build your product — but to help you launch it smoothly, repeat it consistently, and scale it confidently.

✓ DFM review and risk checks prevent last-minute design or assembly failures

✓ Alternative sourcing and cost optimization reduce shortages and price shocks

✓ We help control cost and process stability even at prototype or pilot runs

✓ Production readiness ensures today’s prototype won’t block tomorrow’s volume

✓ Clear, transparent communication replaces uncertainty and follow-ups

✓ Rapid prototyping supported by controlled QA processes

✓ Quality assurance focused on long-term reliability, not just passing inspection

Industry Application

Our solutions power diverse applications across industries – from consumer electronics and automotive systems to medical devices and industrial automation. Discover how our integrated capabilities in PCB fabrication, FPC manufacturing, and precision SMT assembly deliver the quality, efficiency, and reliability your projects demand.

Consumer Electronics

Helptron produces affordable PCBs for gadgets like speakers, routers, and kitchen appliances. Run small or large batches smoothly with our SMT service – good quality without high costs.

Automobile

Get quality PCBs & flexible circuits for car dashboards, lights, and sensors. We follow automotive standards, and our SMT service securely mounts parts to survive bumps and vibrations.

Medical

Take safe patient monitors and medical tools with our certified PCBs. We use clean assembly areas and check every board carefully for reliability.

Lighting

Create better LED lights and signs with our heat-dissipating aluminum PCBs and bendable circuits. Our efficient SMT production keeps your lighting projects bright and on time.

Smart Home

Build wearables, trackers, and smart home gear with our compact PCBs and thin flexible circuits. Our practical SMT lines handle small parts well, balancing performance and cost.

New Energy

Power your green innovations with high-reliability PCBs engineered for extreme environments. Our rigid-flex PCBs withstand high-voltage fluctuations in solar inverters & BMS, while automated SMT assembly ensures precision mounting of heat-sensitive components for wind power controllers.

Trusted by Innovators Across Industries

Discover More About Us

Your One-Stop Electronic Manufacturing Partner

When you work with Helptron, you’re not just choosing a manufacturer —you’re choosing a partner responsible for whether your product ships on time, works as expected, and scales without surprises.

We support you from early design and engineering review through PCB manufacturing, assembly, and final system build — so issues are identified before they reach production, not after they become costly problems.

Whether you need PCB fabrication, turnkey PCBA, box build assembly, cable harnesses, plastic injection molded parts, or full supply chain coordination, our role is the same: to simplify your manufacturing, reduce risk, and keep your project moving forward without constant intervention.

So your product meets spec, meets schedule, and meets expectations —without you needing to be there to make it happen.