Helptron

Turnkey PCB Assembly Built to Prevent Production Failures

We take ownership of sourcing, assembly, and validation, not just placement and soldering, so you don’t discover problems only after boards are populated.

Turneky PCB Assembly

Turnkey PCB assembly is a comprehensive manufacturing solution that a manufacturer handles every aspect of the PCB production process—from sourcing components and fabricating the bare board to assembling, testing, and shipping the finished product. This comprehensive approach eliminates the need for customers to coordinate between multiple vendors, reducing lead times, minimizing errors, and simplifying supply chain management.

Approach

Our Values

Turnkey assembly is not about “buying parts and assembling boards” —

it is about controlling risk across sourcing, assembly, and validation.

01

Engineering-Aligned BOM & Material Control

Before any assembly begins, we review your BOM from a production perspective:

- Availability, lifecycle, and lead-time risk

- Approved alternatives and substitution strategy

- Package, footprint, and assembly compatibility

- Cost vs. reliability trade-offs

02

Assembly Planned Around Real Production Conditions

We align assembly planning with your actual requirements. Boards are assembled for repeatability, not just first-pass success.

- SMT / THT process matching board design

- Panelization and stencil considerations

- Assembly sequence planning for mixed-technology boards

- Yield-focused setup for prototypes and pilot runs

03

First Article Validation Before Scale-Up

Every batch follows a controlled ramp-up process. This prevents small issues from turning into large-scale scrap.

- First Article Assembly (FAA)

- Functional validation where applicable

- Engineering sign-off before volume production

Capability

Turnkey Assembly Capability

From component sourcing and bare PCB fabrication to assembly, testing, and final delivery, the entire process is coordinated as one controlled workflow

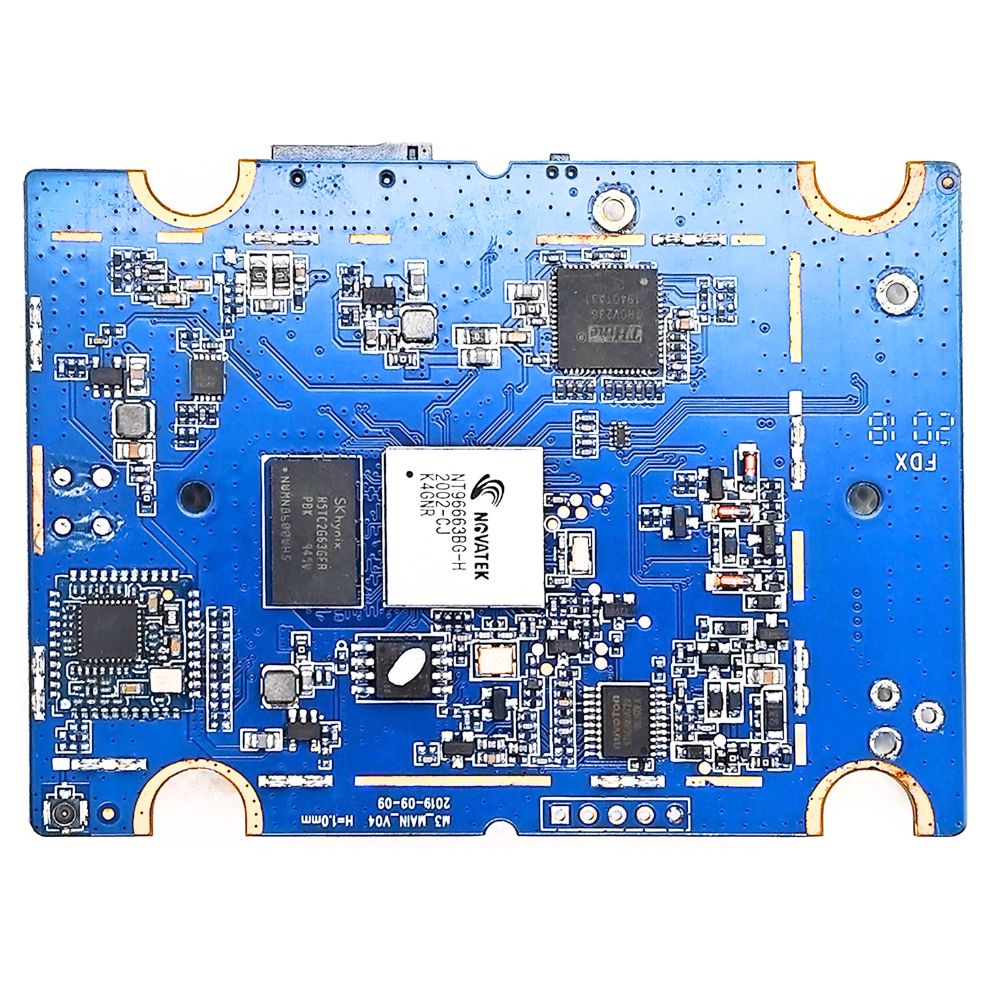

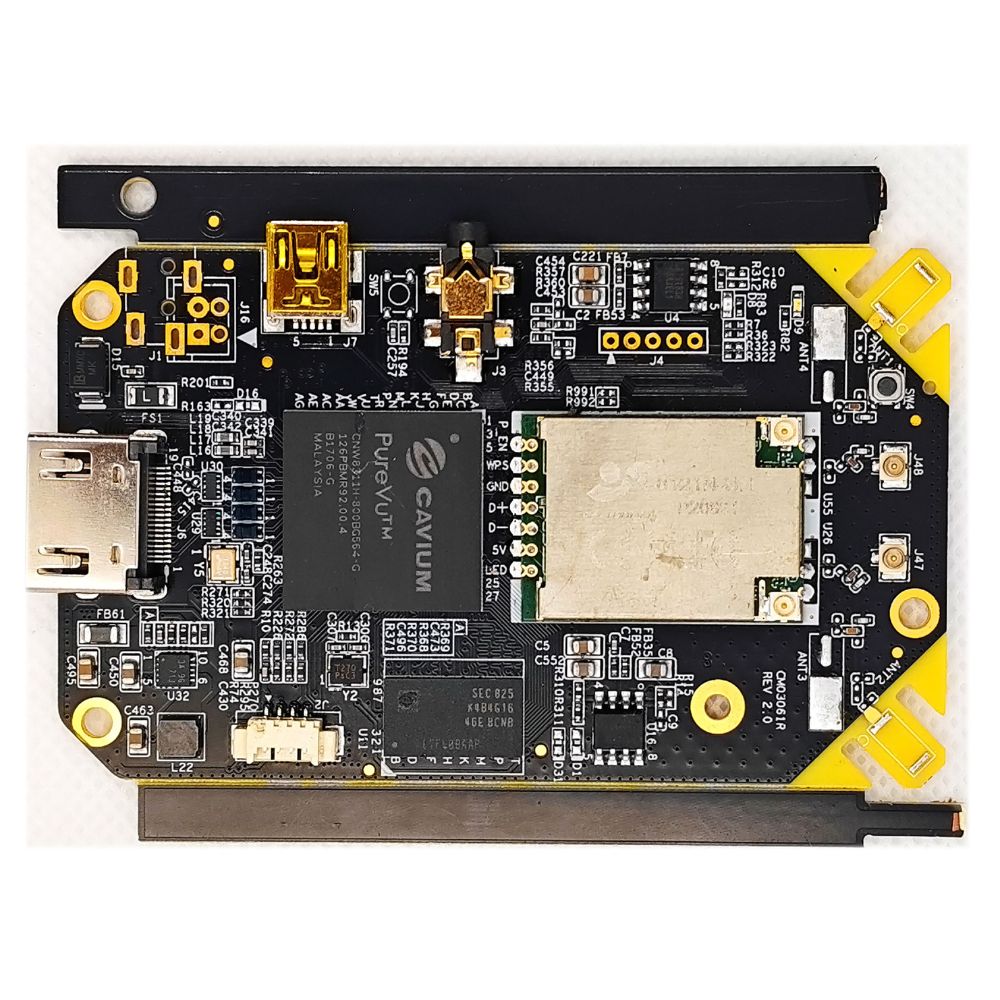

Printed Circuit Board Assembly Scope

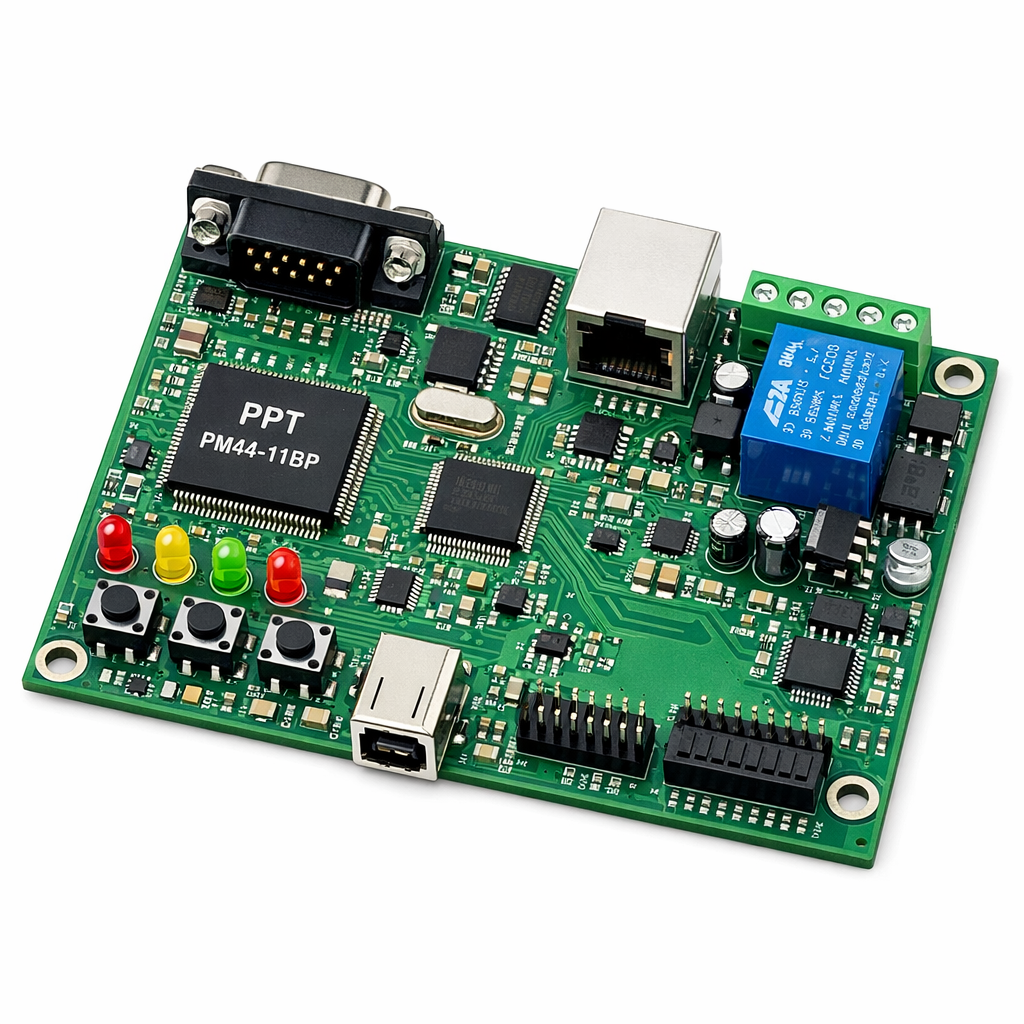

- SMT, THT, and mixed-technology PCB assembly

- Fine-pitch, high-density, and space-constrained designs

- COB and complex package assemblies

- BGA rework support for design changes and issue recovery

- Consistent build quality across multiple revisions

Production & Process Control

- Multiple SMT pick-and-place lines with through-hole insertion

- Lead-free RoHS-compliant assembly lines

- Hot air reflow and wave soldering processes matched to board design

- Documented process control to reduce batch-to-batch variation

- Trained technicians focused on repeatability and yield

Assembly Quality & Test Assurance

- AOI for placement accuracy and solder joint inspection

- ICT for electrical validation and assembly integrity

- Repeatable inspection standards across builds and batches

- Defined inspection criteria aligned with product criticality

- Quality gates are integrated into each production stage

Material & Component Scope

- Active and passive components

- Customer-specified or custom parts

- Approved alternative sourcing when shortages occur

- Full traceability for compliance and lifecycle control

Volume & Program Support

- Prototype and EVT builds for fast design validation

- Pilot and low-volume production for market entry

- Stable mid-volume manufacturing for ongoing programs

- Scalable capacity without process requalification

Compliance & Workforce

- Lead-free RoHS-compliant production lines

- Quality-assured processes operated by trained technicians

- Continuous skill training to support complex assemblies

Challenges & Outcomes

Turnkey PCB assembly becomes high-risk when materials, design changes, and production timing fall out of sync, but works best when one team owns the entire process — not just individual steps.

Challenges We Solve

- BOMs that appear complete, but include EOL or long lead-time components

- Component substitutions made without full assembly or functional validation

- Late-stage design revisions after materials are already ordered

- Assembly or performance issues only discovered during FAI or final testing

Outcomes You Want

- Fewer last-minute BOM or sourcing surprises

- Higher first-pass yield during assembly

- Reduced rework, scrap, and schedule risk

- More predictable cost and lead time

- Confidence when moving from prototype to volume production