Flexible PCB Manufacturing

✓ Wide Range FPC Production ✓ NO MOQ Required ✓ IN-house Testing

✓ DFM Support ✓ 24/48H EXPRESS service

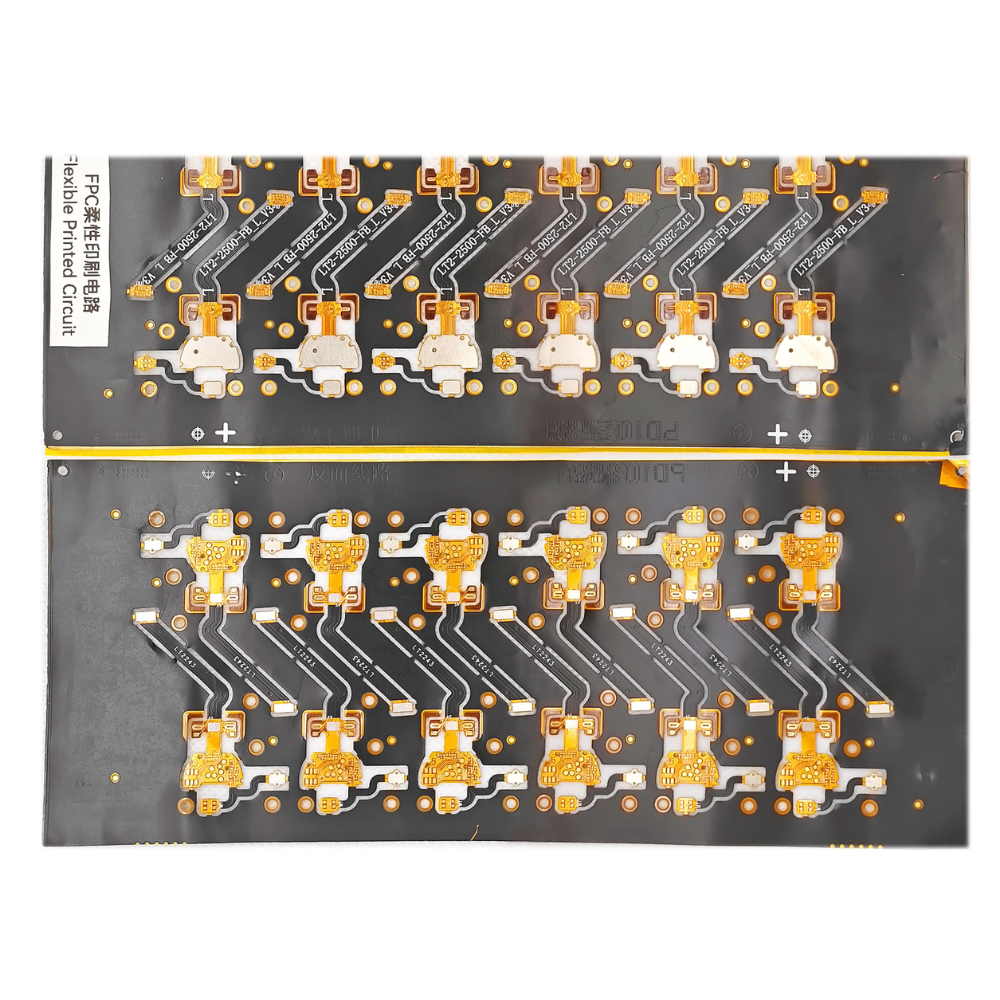

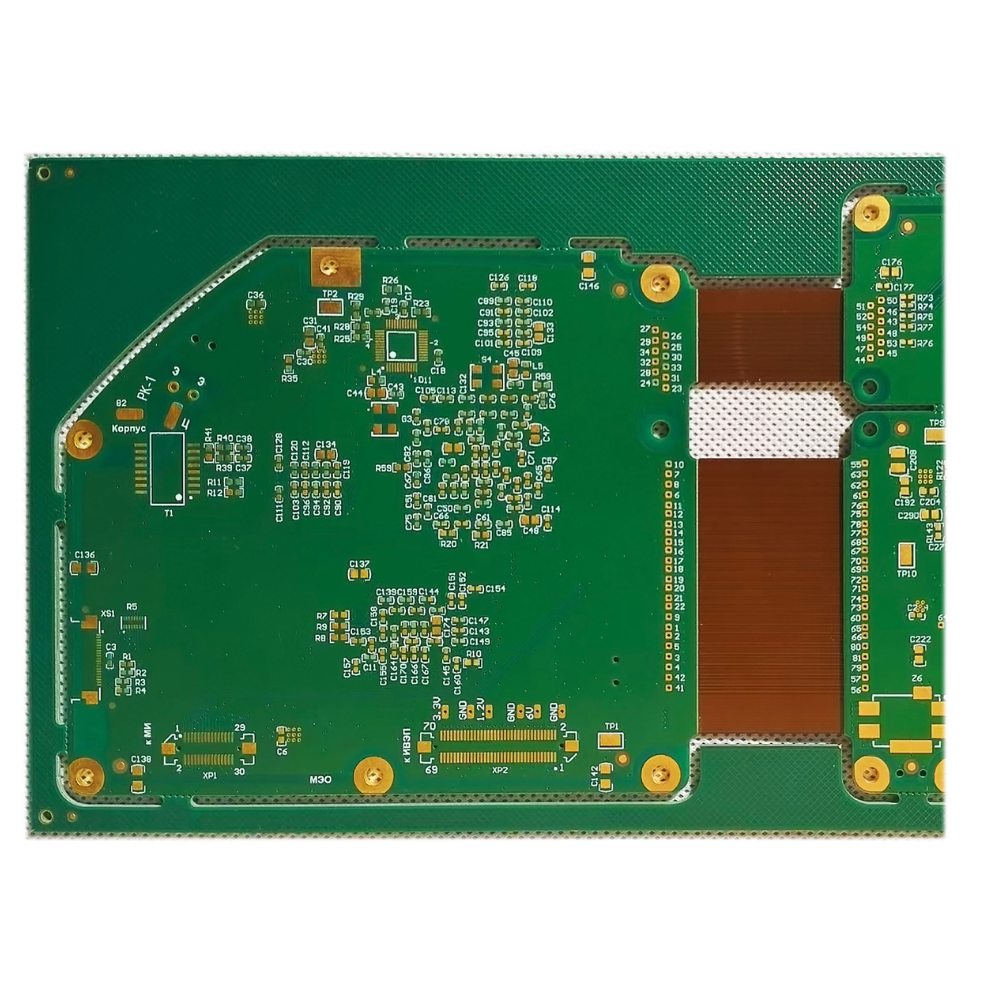

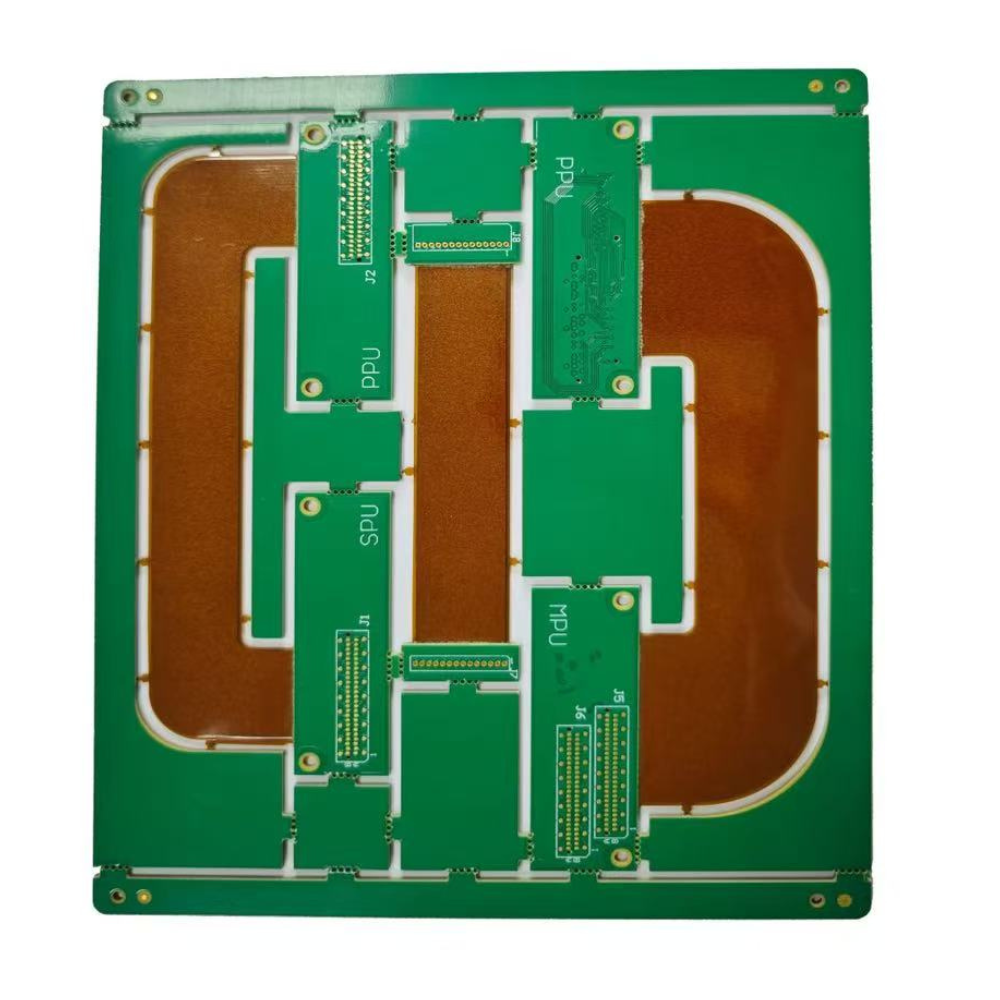

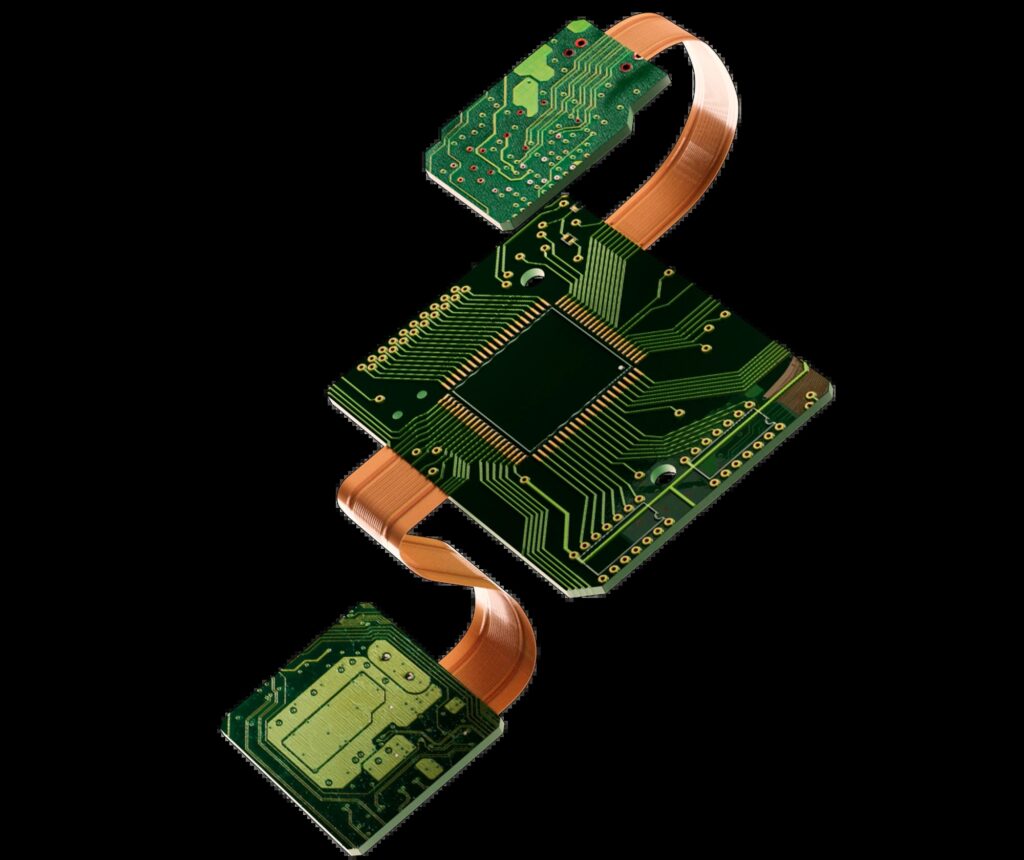

What is a Flexible Printed Circuit Board (FPCB)

Also known as a flex circuit, it is a type of electronic interconnect that uses a flexible plastic substrate, typically polyimide(PI) or polyester(PET) instead of the rigid fiberglass(FR4) used in traditional PCBs. This allows the circuit to bend, fold, and twist into complex three-dimensional shapes or move dynamically during operation.

FPCB Production Features

Full-Spectrum Production Flexibility with Zero MOQ

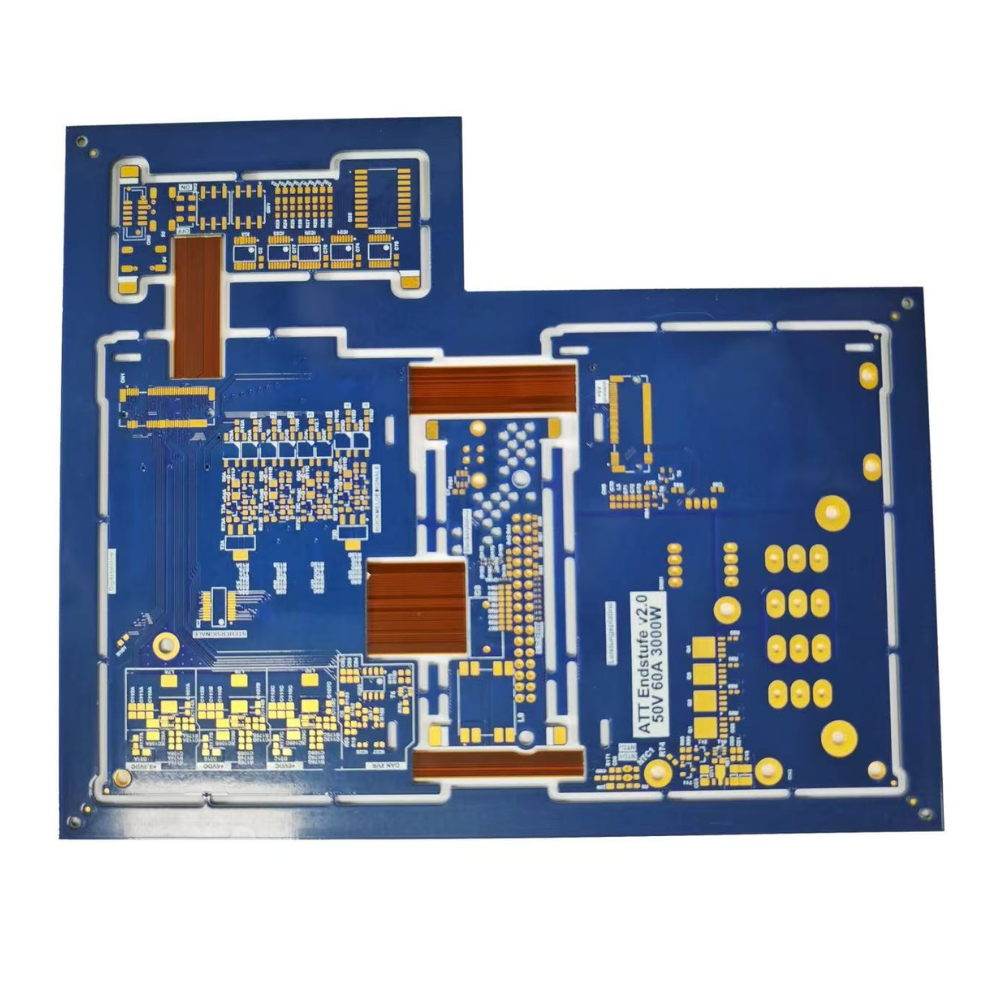

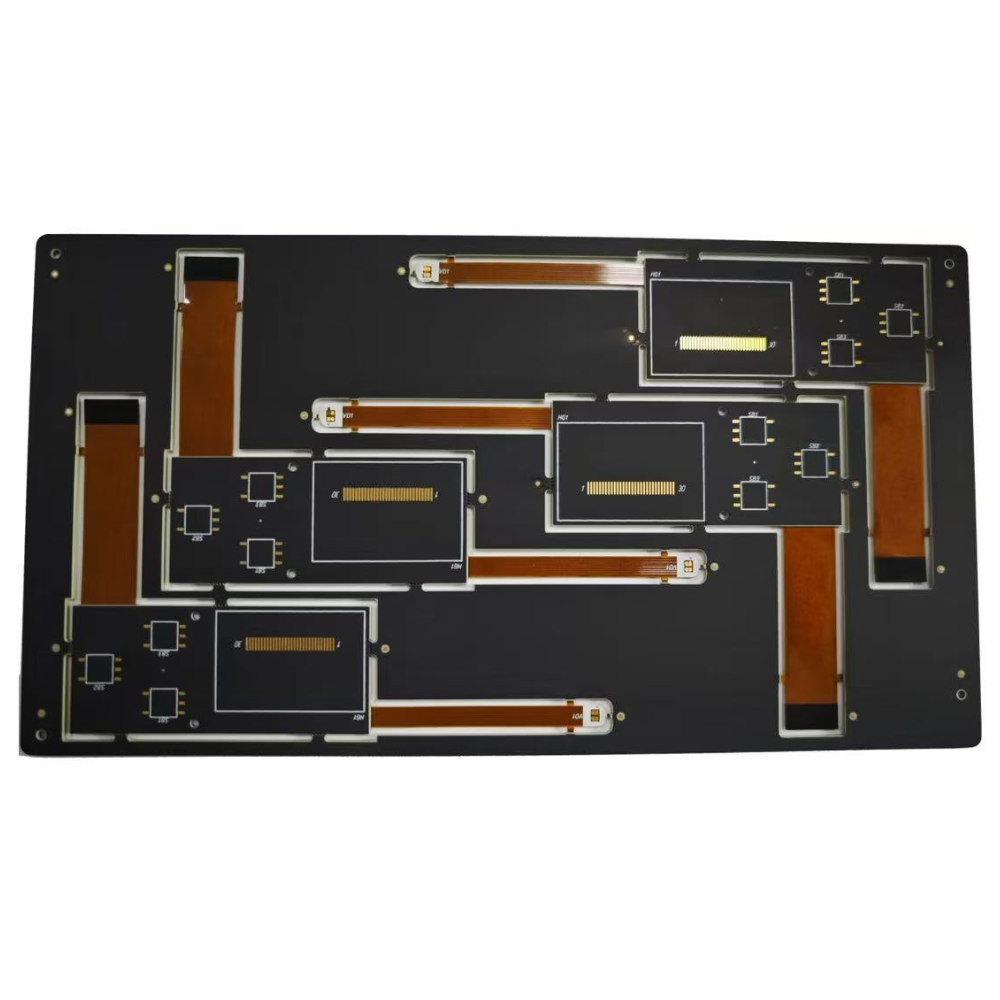

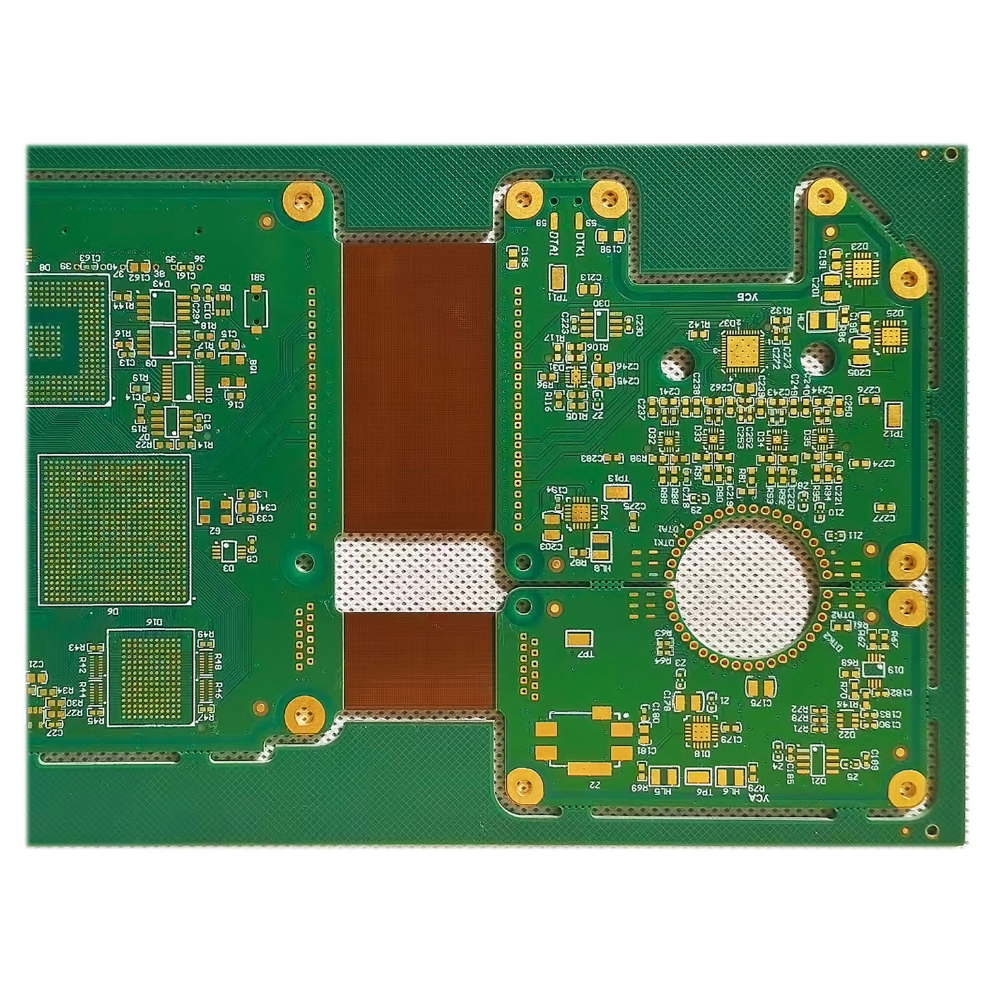

Offers versatile manufacturing of various FPC types (single-layer to rigid-flex) from prototyping to mass production, supporting orders as small as 1 piece with no MOQ limits.

Versatile Industry Applications

Provides reliable FPCs for diverse sectors like wearables, smartphones, medical devices, automotive systems, and industrial sensors to meet industry-specific needs.

Strict Manufacturing Parameter Control

Ensures strict control over layers (1-6), sizes (up to 250×600mm), hole diameters (0.15-0.2mm), line widths/spacing, and other critical production parameters.

Comprehensive Surface Treatment Solutions

Delivers multiple surface finishes (Ni-Au, Sn, OSP) with defined thickness ranges for nickel, gold, and tin layers to suit different application requirements.

Integrated Ancillary Service Package

Supplies end-to-end assembly support, customization options (outlines, panelization), and enhancements like stiffeners and EMI solutions.

Flexible Delivery Time and After-sales Guarantee

Offers flexible lead times (3-12 working days) with expedited options, plus 100% after-sales support and pre-production samples for quality verification.

FPCB Manufacturing Capability

From rapid prototypes to production-ready FPCB ( Flexible Printed Circuits), Helptron Electronics provides end-to-end FPC manufacturing with speed, precision, and full material flexibility. Our FPCs power products across wearables, medical devices, consumer tech, industrial sensors, and more.

| Items | Standard | Limitation | |

| Layers | 1-4L | 6L | |

| Max Size | 250*300 | 250*600 | |

| Min Hole Size | 0.2 | 0.15 | |

| Hole Position Tolerance | +- 0.05mm | +- 0.03mm | |

| Hole Wall CU Thickness | 8um To 12um | 15um To 20um | |

| Line Width / Space | 1/3oz: 2.4mil/2.4mil 1/2oz: 3.0mil/3.0mil 1/1oz: 4.0mil/4.0mil 2oz: 6mil/6mil | 2mil/mil 2.4mil/2.4mil 3mil/3mil 4mil/4mil | |

| Trace-to-Board-Edge Distance | 0.2mm | 0.15mm | |

| Coverlay Registration Tolerance | 0.2mm | 0.15mm | |

| Coverlay Openning-to-Trace Spacing | 0.1mm | 0.05mm | |

| Adhesive Squeeze-Out | 0.15mm | 0.05mm | |

| Stiffener Registration Tolerance | +- 0.25mm | +- 0.15mm | |

| Legend | Min Width: 0.15mm Min Height: 1.0mm Shift Tolerance:+-0.3mm | 0.12mm 0.8mm +-0.2mm | |

| Surface Treatment | Deposition Ni-Au Electroplate Ni-AU Electroplate Sn OSP | Ni80-200uinch/Au1-3uinch Ni80-240uinch/Au1-3uinch 100-1000uinch 0.2-0.5um | Ni80-100uinch/Au 4uinch Ni80-120uinch/Au1-50uinch 100-150uinch 0.5-1.0um |

| Steel Rule Die Tolerance | +-0.3mm | +-0.2mm | |

| Hard Tooling Tolerance | +-0.1mm | +-0.05mm | |

| Gold Finger Shift Tolerance | +-0.1 | +-0.05 |

Consult With Special Specs If The Table Above Can Not Meet Your Requirements.

FPCB Manufacturing Helping Center

What is your standard lead time for FPC orders?

What types of FPCs do you manufacture?

What are the advantages of using flexible printed circuit boards?

What materials are used in flexible printed circuit boards?

Do you support SMT assembly on flexible PCBs?

Can I request a sample before committing to a bulk order?

What happens if there’s a defect or delivery issue?

How do you prevent damage to FPCs during transportation?

Can you help reduce costs for high-volume or long-term projects?

I have tight deadlines — can you offer fast-turn or expedited service?

Can you provide panelized FPCs or customized shapes?

Can you provide panelized FPCs or customized shapes?

Can you manufacture flexible circuits with impedance control?

What is the minimum order quantity (MOQ) for FPC production?

Products

PCB Assembly Gallery