Helptron

IoT Devices Contract Manufacturing

End-to-End Engineering-Driven Contract Manufacturing For IoT Connectivity Devices

IoT Device Contract Manufacturing

In today’s connected world, IoT devices power smart homes, industrial automation, asset tracking, wearable tech, and more. These products require precision electronics, robust connectivity, and scalable production — all while keeping time-to-market short and quality high. At Helptron, we specialize in contract manufacturing of IoT hardware — providing reliable production solutions that support your product from prototype to production and full lifecycle scaling.

Why IoT Device Manufacturing Is Different

IoT devices demand not just precision electronics, but robust connectivity, uptime reliability, and seamless field performance. They combine sensors, wireless modules, embedded firmware, power systems and long-term field reliability— and are often subject to frequent design iterations. This complexity introduces risk at every stage of the manufacturing lifecycle.

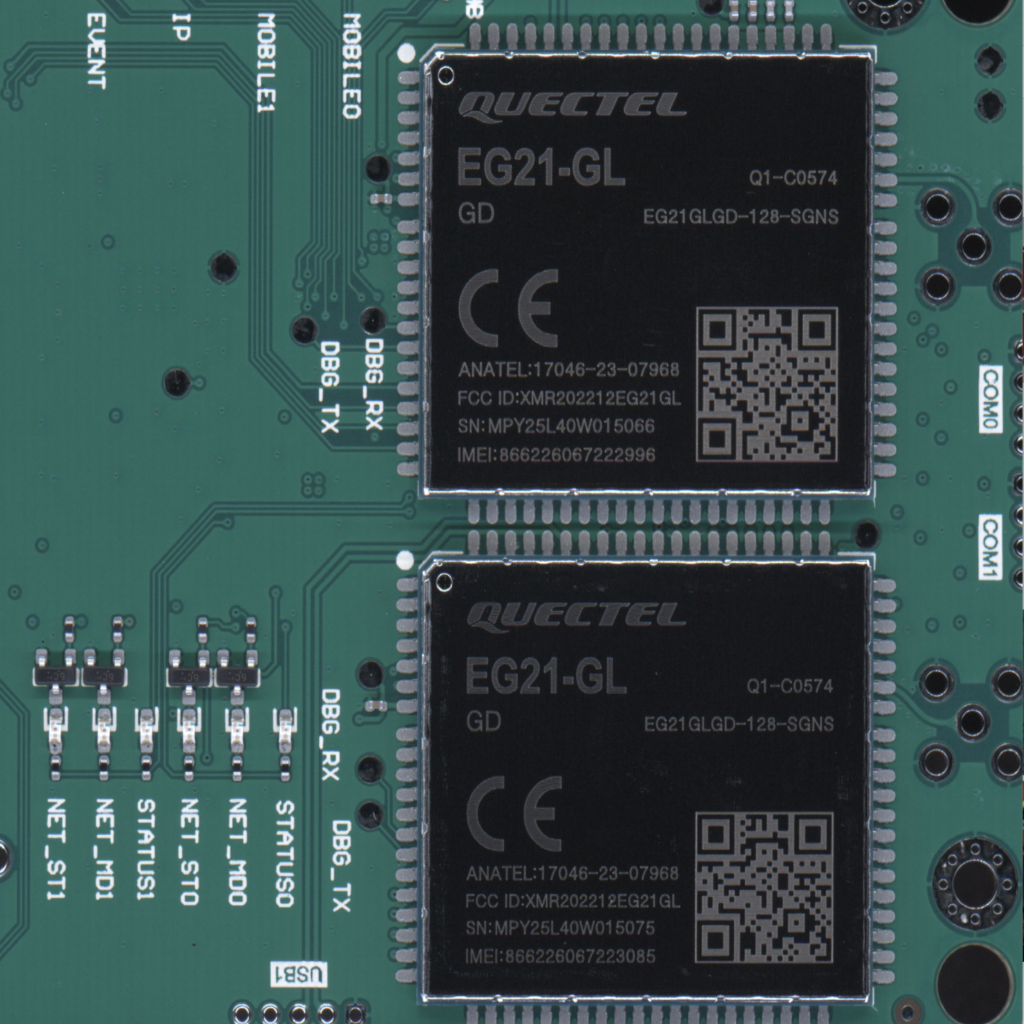

The “Connectivity ” demonstrates how advanced connectivity systems require manufacturing partners who deeply understand both hardware and network implications. In real projects, designs often continue to evolve even when production schedules are already locked.

With Helptron, you get an engineering-driven partner who understands both IoT design challenges and production realities. — with repeatable quality, engineering-optimized production, and scalable contract manufacturing processes.

Engineering-Driven Manufacturing

IoT products — from multi-path communicators to SIM-managed routers — depend on consistent performance across networks, environments, and deployment scenarios.

Helptron embeds engineering throughout the production lifecycle. This approach prevents costly field failures and reduces iteration cycles on complex IoT devices.

01

Requirement Alignment

We begin with detailed reviews of your design files, BOM, functional requirements, and compliance needs

02

Design review & DFM

Our Engineer will ensure the design layout supports signal integrity and assembly yield

03

Prototype and FAI

Every build starts with First Article Inspection to eliminate early-stage risks.

04

Functional & RF testing

validate connectivity and protocol reliability

05

Production readiness

Once validated, we scale your builds with controlled quality and transparency.

06

Production monitoring

continuous quality analytics and risk control

Capability

Comprehensive Contract Manufacturing Services for IoT Devices

End-to-End Solutions Tailored to Connectivity Products

PCB Manufacturing

High-complexity, Multi-layer, high-density boards, controlled impedance, production-grade boards.

PCB Assembly (PCBA)

High-precision SMT lines supporting 01005 and BGA / THT / mixed technology for complex IoT board

Material Procurement

Managed sourcing for IoT-specific components like modems, cellular modules, Wi-Fi chips, MCU, Antenna.

Box-Build Assembly

We assemble enclosures, power systems, connectors, displays, and internal components as one integrated system.

Test Fixtures & Functional Testing

Support ICT, functional testing, and application-specific test fixtures to ensure each device performs as intended.

Custom Injection Molded Parts

Support custom enclosures and structural parts designed for assembly compatibility and production repeatability.

Custom Cable & Wire Harness

We build and test cable assemblies and wire harnesses tailored to your routing, pinouts, and mechanical constraints.

Regulatory & Compliance Support

We support manufacturing alignment for FCC, CE, RoHS, and REACH requirements through controlled processes and documentation.

Challengs & Outcomes

Your IoT product deserves a partner who understands connectivity — not just assembly.

Challenges We Solve

- Frequent firmware and hardware revisions

Design updates continue well into production, creating version control and build consistency challenges. - Supply chain disruption for critical connectivity components

Wireless modules, sensors, and key ICs face availability swings that can delay builds. - Test complexity for wireless and sensor performance

Functional testing goes beyond power-on — RF, sensing accuracy, and system behavior must be validated. - Miniaturized boards and constrained enclosures

Compact designs leave little margin for assembly, thermal, and tolerance errors. - High-quality expectations for long-lifecycle devices

IoT devices are expected to operate reliably for years, often in harsh or unattended environments.

Outcomes You Want

- Stable builds even as designs evolve

Your hardware remains manufacturable and controlled, even with ongoing firmware or PCB updates. - Predictable production despite supply chain volatility

Alternative sourcing and early validation protect your delivery schedule. - Confidence in real-world device performance

Wireless, sensors, and system behavior are verified before devices ship. - Assemblies that fit, function, and scale

Electronics, plastics, and cables integrate smoothly inside tight enclosures. - Reliable products built for long service life

Consistent quality from pilot runs to volume production — without surprises in the field.

Wide Range IoT Products We Support

We support IoT device companies operating in connectivity-critical environments, and tailor production strategies to meet each product’s performance, certification, and deployment requirements, including

- Cellular IoT communicators (4G/3G/LTE/CAT M1)

- Multi-path connectivity routers

- Alarm and sensor communication modules

- RF and embedded IoT platforms

- Connectivity gateways for cloud and monitoring systems

Our experience includes multi-generational products that have been manufactured and maintained over many years under strict confidentiality.